What is a Selector Switch? + Buying Guide

Selector switches, also known as rotary switches, are a type of electrical switch used in various industries and systems. This type of switch was introduced in the 1980s and quickly gained attention. The initial structure of these switches consisted of pins, which gradually evolved into a more modern form and structure. Selector switches were first introduced in the United Kingdom and are now used in various industries and applications, including electrical, automation, and industrial controls.

Selector switches are used as vital tools in control and safety systems. The diverse design of these switches allows for selection and switching between multiple modes or functions. This article, by examining the details and features of these switches along with a comprehensive buying guide, helps you make the best use of these essential devices in your projects and systems.

What is a Selector Switch?

A rotary or selector switch is considered one of the very practical switches in various industries. This type of switch is mostly used in the low-voltage range and is employed to change the status and control electrical circuits. Additionally, rotary switches are used for disconnecting and connecting three-phase or clockwise and counterclockwise rotation of motors.

In simpler terms, a selector switch or rotary switch can be described as a semi-independent manual switch. Generally, a switch is considered a device that interrupts or connects the current flow. In this context, the term “semi-independent manual” refers to directly applying energy or pressure manually.

One of the reasons for the popularity of rotary switches in industrial electrical panels and control systems is their simple operation and cost-effectiveness. Selector switches are made of wear-resistant materials, and their rotary switches are used for interrupting or connecting operations. These switches are used in the switching of electrical currents, interruption in switching, and control of motors.

Wide Variety of Types of Selector Switches

Selector switches hold a special position in various production lines and industrial machines. This diversity is extensive not only in terms of practicality but also in terms of types. Below is an introduction to the types of selector switches:

- Single Pole Switch (01): These switches are used for one-way direction in electrical circuits.

- Double Pole Switch (02): Double-pole switches are used for two-way direction in different circuits.

- Star-Delta Switch: This type of switch is used to control electric motors in star or delta configurations.

- Ammeter Switch: It is used to measure electrical current.

- Voltmeter Switch: These switches are used to measure electrical voltage.

- Single-Phase Clockwise-Counterclockwise Switch: Used for controlling the direction of rotation of single-phase motors.

- Three-Phase Clockwise-Counterclockwise Switch: Used for controlling the direction of rotation of three-phase motors.

- Dalandar Switch: Used for controlling Dalandars in electrical systems.

- Multi-Position Selector Switch: These switches have the ability to change between multiple modes in electrical circuits.

Each of these types of selector switches is recognized in the market with its specific codes, so paying attention to these codes is essential when making a purchase.

Differentiation of Selector Switch Types Based on Function

Selector switches, based on their function, are divided into various types. The following introduces these types:

- Single-Pole Single-Throw Switch (Single Mode): This type of rotary switch, or the so-called locking switch, is used to interrupt or connect between two terminals. This switch has one input and one output, as well as a connection that, when the light is on, allows current to flow through the terminals.

- Single-Pole Double-Throw Switch (Two Modes): This type of selector switch, with three terminals, provides one input and two output terminals. The COM terminal is used to control a three-way circuit.

- Double-Pole Single-Throw Switch (Single Mode): This two-pole switch has two separate circuits and, with one push, controls two different circuits simultaneously. With four terminals, it brings two inputs and two outputs and is used to turn on or off two different circuits.

- Double-Pole Double-Throw Switch (Two Modes): In this type of selector switch, two separate circuits are connected to each other with two inputs and two outputs. The switch controls the routing of contacts based on the number of paths.

Each of these types of selector switches, with their unique features, is used in various circuits and electrical systems.

Wide Application of Selector Switch

What are the various applications of selector switches or rotary switches in different industries? This question might make you ponder. Selector switches are utilized in various sectors, including:

- Plastic, Glass, and Metal Production: In the production of materials such as plastic, glass, and metals, selector switches are used to control circuits and change statuses.

- Packaging, Warehousing, Material Transportation, and Equipment Movement: In processes related to packaging, warehousing, material transportation, and various equipment movements, selector switches are employed for precise execution of different tasks.

- Heavy Equipment and Machinery Manufacturing: Industries involved in the production of heavy equipment and machinery use rotary switches for control and optimal performance.

- Food and Beverage Industries: In the production processes of food and beverages, selector switches are used for precise management of production processes.

- Oil and Gas Refining and Extraction: In the oil and gas refining and extraction industries, rotary switches are used to control various equipment and processes.

- Automotive Industries: In the manufacturing of automobiles and related components, selector switches are used for controlling and adjusting various elements, including lighting and direction.

Description of Interlock Operation in Selector Switch

Rotary safety switches, with their red and yellow handles, have the ability to create an interlock state. This interlock state means that when the switch is in the off position, the panel door opens. Additionally, selector switches with interlocks can have markings and locks in the off position.

When are interlock selector switches useful in internal panel equipment? These switches are used when they are in the off position, making them capable of safely disconnecting under load, and they can disconnect the largest electric motor in the network.

Installation and Wiring Guide for Selector Switches

Selector switches come in various types, each requiring its specific installation and wiring. Below is an examination of the installation and wiring procedures:

- Multi-Position Selector Switch: This type of selector switch or rotary switch has a simple structure. It has multiple inputs and outputs that connect to each other. Outputs are connected to separate consumers. Placing the switch in position one turns on consumer one, and placing it in position two turns on consumer two. In this state, consumer one turns off, and the process continues.

- Star-Delta Selector Switch: These switches have 3 main inputs and 6 outputs that connect to the electric motor.

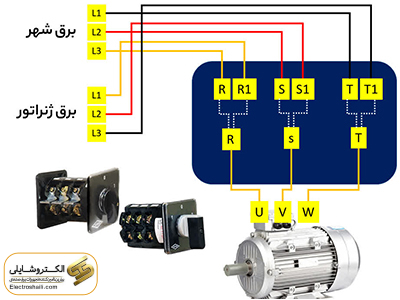

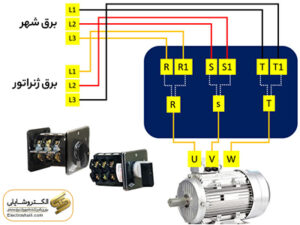

- Counterclockwise-Clockwise Three-Phase Selector Switch: Designed based on the change in the speed of three-phase motors. These switches have one, two, and zero modes. The zero mode is used for turning off. Mode one is for counterclockwise, and mode two is for clockwise.

Key Details in Purchasing Selector Switches

To choose the most suitable selector switch, consider the following points. These switches play a crucial role in supplying power to industrial devices and various equipment, and their proper selection has a significant impact on safety and energy supply to industrial devices.

- Build Quality: Opt for switches with high resistance and stable structures.

- Environmental Resistance: Ensure that your selected switch has sufficient resistance to dust and water.

- Type and Application: Evaluate the type of switch and its applications based on your needs.

Conclusion

With all the information provided, you can now confidently choose your selector switch. These essential devices in the industry contribute to increased productivity and the supply of energy to various devices. By considering the selection tips and using different types of selector switches, you can easily meet your needs and have a significant impact in the industrial world.