What is Push Button or Push Switch?

Push button or push switch is a switch mechanism used to control the operations of a system or device. The body and components of this tool are made of materials such as plastic, metal, or bakelite to ensure proper resistance and hardness. Metal and plastic push buttons also have auxiliary contacts that improve their functionality. These tools, using their switch mechanism, provide more precise control over the desired system or device.

The surface of the push button, also known as the push button head, can be either smooth and flat or recessed, including features like a mushroom-head or a locking key. This push button head is usually designed in a round or square shape, providing greater flexibility in use and placement in various systems and devices.

The push button or push switch head can be pressed in several ways:

– Surface pressing with a finger

– Deep pressing

– Hitting

– Fist pressing

These types of pressing provide a diverse range of control options for using the push button, from light finger pressure to deep pressure and even through hitting or fist pressing.

What are the Components of Push Button?

Push button structures include a piston, a return spring, and a set of contacts as an essential unit in control systems and electrical tools. In the example below, a normally open (NO) push button is shown, where in the open state, no current passes through it. When pressure is not applied to the push button, the piston returns to the open state with the help of the spring. On the other hand, normally closed (NC) push buttons, like the example below, are used to control opening and closing a circuit. The contacts are normally closed, allowing current to flow in the control circuit. By pressing the push button, the contacts open, preventing current from entering the control circuit. These buttons are known as momentary contacts because the contacts are open only as long as pressure is applied to them.

Schneider Push Button Operation:

The Schneider push button is a tool with a distinctive mechanism that, when pressed and the desired action is performed, automatically returns to its initial state through an internal spring. In the lockable example, the push button locks after being pressed and can only return to its initial state by rotating the mushroom-head-like XB5AS542 in a clockwise direction.

In the lockable example with a key, such as XB4BS

9442, using the key embedded on the mushroom-head, allows locking the push button and preventing any unauthorized pressing and improper operation. This type of use is crucial in vital operational areas to restrict access only to qualified individuals.

Push buttons are coded based on their color, with each function assigned a specific color. This coding prevents mistakes in pressing buttons by operators.

The Schneider XB4BW3165 push button, with a chrome metal body, spring return mechanism, and white color for BA9s lamp without a lamp, is utilized. It has 1NO+1NC auxiliary contacts, and the supply voltage for operating this product is less than 250 volts.

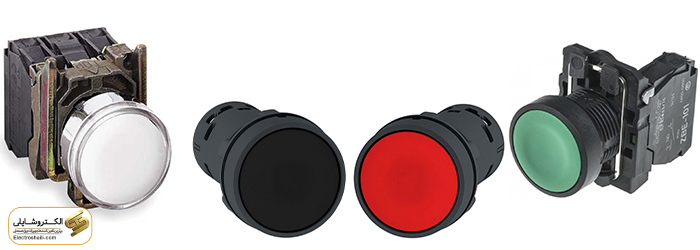

Various Schneider Push Buttons:

Various types of push buttons or switches are often used in electrical systems to control and interrupt contactors. Push buttons are momentary switches that, when pressed, move the movable blades and connect or disconnect two contacts.

This operation is usually performed by human hand, but in some devices, pedals (foot-operated) and mechanical movements of the device and machine (microswitches) are also utilized. In control circuits, various types of push buttons or switches are often used, including start buttons, stop buttons, and a combination of both. The following will carefully examine various Schneider push buttons.

Start Button:

The start button is a tool that, when activated or pressed, connects the normally open contact. This button is normally open and closes momentarily with a touch. Inside the start button, a spring is placed that facilitates the return to the initial state. The usual color for start buttons is green or black, but there may be variations in other colors.

Stop Button:

The stop button is a tool that, when activated or pressed, disconnects the connected contact. This button is normally closed and opens momentarily when pressed. Inside the stop button, there is also a spring that provides the return, but the contactor circuit remains in the connected state using an auxiliary blade (normally open contact). In cases where no auxiliary is used, the circuit may become unstable. The usual color for stop buttons is red.

Start-Stop Double Button:

The start-stop double button is a unique combination of the start button and the stop button used in electrical systems. In this type of button, a two-digit number specifies the number of closed blades (stop) and open blades (start). For example, the start-stop double button with the number 11 identifies a single start button with the number 10 and a stop button with only the number 01. The number 32 indicates a compound button with five blades, three of which are start and the other two are stop. The arrow direction on the button symbols indicates the force direction for the spring to return to the initial state.

In electrical diagrams, devices are often in the off state (normally open), and the blades connect from left to right. Connection diagrams are drawn vertically, especially for control circuits.

Structure of Schneider Push Buttons:

The structure of Schneider push buttons consists of a combination of a piston, a return spring, and a set of contacts. In the image below, a normally open (NO) push button is depicted, which, in the open state, does not allow any current to pass. When pressure is applied to the push button, the piston returns to the open position with the help of the spring.

Normally closed (NC) push buttons, as shown below, are used to open and close a circuit. In the normal state, the contacts are closed, allowing current flow in the control circuit. When the push button is pressed, the contacts open, prohibiting current from entering the control circuit. These types of push buttons are of the momentary connection type, as the contacts remain open until pressure is applied to the piston.

Push buttons are designed in such a way that when one push button is in the start state, it can act as a stop for another circuit. Push buttons with normally open (NO) and normally closed (NC) contacts are pressure buttons. In some cases, both types of normally open and normally closed contacts are used in one push button. 22 mm pressure buttons can control up to 6 circuits at most, while 30 mm pressure buttons can control up to 16 circuits in the maximum configuration.

Schneider Push Button Color Coding:

According to the international standard IEC-204-DIN 4818, color codes are recommended for push buttons and indicator lights. These color codes are used in building panels and indicator lights. Below are the color codes for indicator lights used in building panels and control devices:

– Red Push Button:

Used to interrupt operations. By pressing this button, one or more motors can be turned off.

– Mushroom-shaped Red Push Button:

Used for emergency shutdown in control circuits, accompanied by a yellow label.

– Green or Black Push Button:

Used for the on or starting state, such as connecting the circuit to the power source, starting one or more motors with specific functions, or starting the electrical parts of a machine.

– Yellow Push Button:

Used for starting in a non-normal state, such as starting a motor in the opposite direction of the normal state or starting a motion in a direction away from danger. By pressing this button, power to all previously connected parts is cut off.

– White and Blue Push Buttons:

These buttons can be used as indicators for any other purpose.

Schneider Push Button Control Station:

The use of a control station box for Schneider push buttons for easy installation of manual control equipment and signal lights, including push buttons, emergency stop buttons, and more, is very useful. This box can host various control buttons and signal lights with a diameter of 22 mm, such as the plastic green signal light with code (XB5AVB3) or the emergency stop push button with a mushroom head (XB5AS542).

The Schneider Electric control station box is well-coordinated with the surrounding environment and is fully recyclable. This product is part of the Premium Green product category.

Schneider Electric control station boxes are designed and produced in various types based on user needs, including single-button, double-button, triple-button, etc. For example, the XALD02 shape or the two-button control station box without push buttons is from the Harmony XALD product line of Schneider Electric. This box is made of polycarbonate, and its housing is light gray, while the cover is dark gray.

This product has easy usability and easy assembly capabilities. The suitable temperature for its installation and maintenance is in the range of 40 to 70 degrees Celsius, with an IK03 protection degree according to the EN 50102 standard.

Schneider Emergency Mushroom Head Push Button:

Schneider Electric produces various models and types of electrical push buttons, and one of these models is the Emergency Mushroom Head Push Button. This type of push button belongs to the XB5 series and utilizes a mechanical lock mechanism for emergency commands. The body of this product is made of plastic, and its connections are made of silver alloy. The required voltage for this product is in the range of 120 to 600 volts AC or DC.

In general, emergency buttons or emergency stop switches, as implied by their names, are used for emergency shutdowns in electrical panels. Their function is similar to that of a stop push button connected to a contactor; pressing the push button opens the contactor, issuing an emergency command.

The installation diameter of the XB5 Emergency Mushroom Head is 22 millimeters, and it does not include a signal lamp. It also features a normally closed (NC) contact that operates in a slow-break manner.

Furthermore, the Emergency Mushroom Head push button has a mechanical lock mechanism. This means that by pressing the push button, the product locks, and it can only be unlocked and released by rotating its head clockwise. Therefore, it is recommended to pay attention to these features when purchasing this product for installation in an electrical panel.

Difference Between Push Button and Emergency Key with Emergency Stop Key:

Schneider Electric offers two types of push buttons to the market:

Emergency stop key with a mechanical lock mechanism:

This push button directly opens the circuit. The speed at which the normally closed (NC) contacts open and, consequently, the production of the OFF command, depends on the speed of the pressed push button. In some cases, the OFF command can be generated before the locking mechanism is activated, at a single moment.

Emergency stop key with a trigger operation (latch-release circuit) and a mechanical lock:

The operation of this push button is similar to the previous model, directly opening the circuit. Additionally, the speed at which the normally closed (NC) contacts open and, consequently, the production of the OFF command, depends on the speed of the pressed push button. The energy stored in the spring is used to activate both the locking and unlocking mechanisms, opening the circuit through NC contacts. This means that the locking mechanism cannot be executed without the OFF command, and naturally, the OFF command cannot be produced without locking the system.

Standards and Regulations for Push Buttons and Emergency Stop Keys:

The operation of emergency stop keys adheres to standards and regulations related to devices and machinery. Standards such as 2006/42/EC, EN/IEC 60204-1, EN ISO 13850, and IEN/IEC 60947-5-5 define this operation. In all these standards, it is mentioned that an emergency stop must be accompanied by a locking mechanism, and one cannot be performed without the other.

One of the crucial issues in the application of emergency keys is preventing accidents and ensuring the safety of individuals working with machinery. Standards emphasize the need for a locking capability in emergency stop keys to reduce hazards from electric shock or fire in various industrial environments.

These standards dictate that devices for emergency stops must have the ability to lock. The use of a trigger mechanism may not be necessary, but if present, the device will be safer and less prone to risks, as there is less likelihood of danger.

Summary of the Definition of Push Buttons

In this article from ElectroShield, we have examined various types of push buttons and emergency stop keys from Schneider Electric. Initially, we explored different types of switches, such as start, stop, and start-stop double, explaining the functionality of each. We then delved into the structure of push buttons and the significance of using Schneider control station boxes.

In another section, we discussed the differences between push buttons and emergency keys with emergency stop keys, highlighting their roles in emergency situations and machinery safety. In this part, we also covered the standards and regulations related to the operation of these devices and emphasized safety considerations in their installation and usage.

Finally, we provided information about the color codes of Schneider push buttons and explained how to use these codes in electrical panels and devices. This article offers comprehensive information to the reader, enabling them to ensure safety and better performance in their electrical systems through the proper selection and use of these devices.