Review of Various Pneumatic Key Accessories and Their Applications

In this article from Electroshaili, we intend to examine various types of accessories for pneumatic keys and analyze their unique applications. So, stay with us.

What is a Pneumatic Key?

Pneumatic keys are part of thermal-magnetic automatic devices and have a continuous thermal and mechanical endurance body designed to withstand nominal current. These keys come in two models: three-pole and four-pole, as well as fixed and drawer types, and can be customized based on specific industrial needs. These keys are used in electrical panels as main switches, master keys, or pneumatic automatic keys to meet various industrial requirements.

Types of Pneumatic Key Accessories

To enhance the efficiency and remote control of keys, various accessories are used for these automatic keys, improving their capabilities and functionalities. In this article, we will explore these accessories and their functions, providing you with precise information about the added features to automatic keys.

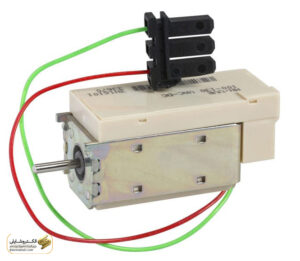

Motorized Pneumatic Key

Motorized pneumatic keys typically utilize a make-and-break structure with charged springs. In this structure, the spring charge of the key is done by the handle gearbox (manual charging mechanism) or an electric motor, connecting the key and making it ready for operation.

By pressing the ON button on the key, the connection is established, and by pressing the OFF button, the key is disconnected. Additionally, in case of a fault, an electronic relay, using sample transformers, detects the fault current and issues the spring discharge command within a specified time. In other words, the current interruption mechanism by the key becomes active.

Another method to charge motorized pneumatic keys is by installing a motor on the key. This method allows remote charging of the key without the need for a key handle. Although the price of motorized pneumatic keys is higher than the manually charged version, it is possible to charge the key manually as well.

Shunt Relay and Under Voltage Relay for Pneumatic Keys

Motorized pneumatic keys use non-metallic (preventing overload) and magnetic coil (resistant to short-circuit current) to protect the circuit. These keys serve as an essential part in lighting and industrial electrical installations, protecting lines and machinery, and in secondary power transformers to protect the transformers.

The application of pneumatic keys is in the input and output feeders, installed on horizontal and vertical busbars. These keys are used to protect motors, capacitors, generators, busbars, and cables. The important point is that the micrology section of motorized pneumatic keys can support various electrical protections.

The control of pneumatic key functions is managed by two relays called the Shunt Relay and Under Voltage Relay. These relays are installed inside the pneumatic keys, and the delay feature in them is the main element in maintaining coordination. If the need for charging pneumatic keys is by an electric motor, it can be ordered with a motor, and two shunt relays can be sent as companions, one of which can be an under-voltage relay.

Motorized pneumatic keys are available with voltages of 110V and 220V AC, and the type of voltage of the motor should be specified during purchase. In most cases, motorized pneumatic keys with 220V AC voltage are chosen.

What Advantages Does a Pneumatic Automatic Key Have?

The advantages of pneumatic automatic keys are very noticeable and effective. These advantages include:

1. Instant Operability: Pneumatic automatic keys, in response to high current or other factors, become immediately ready for operation after the circuit is disconnected.

2. Short Circuit Protection: The design of these keys is such that if the key is closed on a short-circuited circuit, the relay quickly activates and disconnects the circuit.

3. Key Status Control: By using secondary contacts placed in the pneumatic key (four position contacts and one fault contact), the status of the key in different modes of disconnection, connection, or fault occurrence can be determined and displayed in the control room.

4. Network Protection: In some distribution networks, it is necessary for the circuit to be automatically disconnected in case of reverse current or excessive voltage drop, and the necessary alarms to be activated. Pneumatic automatic keys provide this capability.

5. Emergency Use: In situations where automatic or manual entry of emergency generators or transformers is essential for network continuity or periodic maintenance, only pneumatic automatic keys can be used.

Micrological Protection Unit

The micrological protection unit is recognized as a vital accessory for pneumatic automatic keys, providing various electrical protections. This unit protects against short circuits, ground faults, ground leakage, no-load protection, and overload protection. By installing this micrological protection unit on the key, an active control unit is activated, displaying and measuring not only nominal power, voltage, and current values but also providing versatility with adjustable protection thresholds and delays through adjustable screws. These features make this unit a versatile and efficient tool in the field of electrical protection.

Short Circuit Protection in Pneumatic Automatic Keys

Short-term (rms) and instantaneous protection

Essential considerations in selecting the I2T type for short-term protection delay

Ground Fault Protection

Coverage of ground fault or residual current

Use of I2T type for protection delay

Ground Leakage Protection

Functionality without the need for an external power source

Resistance to noise with Class A up to 10A

No-Load Protection

In three-pole automatic keys, no-load protection is not possible.

In four-pole automatic keys, no-load protection is achieved through a 3-state switch.

Unprotected (4P 3d) or No-Load Protection in Ir (4P 4d)

Overload Protection

Real long-term rms protection

Thermal memory: Thermal image before and after relay operation

Precision settings through limiting the range of settings using a different overload protection setting plate can remove overload protection. (When in the OFF position)

Overload Warning

A yellow LED warning light turns on when the current exceeds the set overload threshold.

Communication Option

The COM communication port can send the following information:

Device settings

Relay performance reasons

Readings of maximum values

All ammeter measurements

Micrological protection units protect power circuits. They also provide measurement, display, communication, and maximum current value. They cover type 6 ground fault protection and type 7 ground leakage protection.

Any activation of the AP micrology light or failure of CTs and key micrology is an indicator of a potential malfunction. Also, note that pneumatic key micrology is replaceable.

Micrological protection unit for pneumatic key is divided into four categories: Micrologic A, Micrologic P, Micrologic E, and Micrologic H. The type of Micrologic indicates the level of key protection, which includes Micrologic 2, Micrologic 5, Micrologic 6, and Micrologic 7.

Introduction to the Most Common Pneumatic Key Accessories

Pneumatic key accessories are recognized as vital components for improving the performance and efficiency of these keys. Among prominent accessories are the Shunt Trip Relay, Disconnect Relay, Under Voltage Relay, Auxiliary Contact, Motorized Pneumatic Key, and Micrological Protection Unit. These accessories enable remote control of the key through the Shunt Trip Relay, Disconnect Relay, and Under Voltage Relay.

The Auxiliary Contact also contributes to improving the performance and extensive application of pneumatic keys. The Motorized Pneumatic Key controls the automatic key mechanically, and the Micrological Protection Unit benefits from protection against overload and short circuits. These accessories enhance the efficiency and reliability of pneumatic keys.

Micrological Protection Unit in Pneumatic Key: Ensuring Safety and Optimal Performance

The Micrological Protection Unit, an intelligent electronic initiative in pneumatic keys, automatically protects the device against short circuits, sudden current increases, and even delays in disconnection. This advanced unit, known as Micrologic, using advanced electronic technology, provides precise measurement and control of important parameters.

Final Thoughts

In this article, we have examined various types of pneumatic keys and their applications. Different accessories for these keys were also discussed as essential factors in improving the performance and protection of circuits. Shunt Trip Relays, Disconnect Relays, Under Voltage Relays, Auxiliary Contacts, Motorized Pneumatic Keys, and Micrological Protection Units are among the most important accessories for optimizing the performance and safety of pneumatic keys. These accessories not only enable remote control but also provide protection against overcurrent, short circuits, and other electrical hazards. Through these accessories, pneumatic keys are optimized for various applications, including industrial and electrical installations.