Review of Steering Keys Applications

Steering keys play a crucial role in users’ experience with various devices and systems. These keys, considered as interfaces between the user and the device, have the capability to activate various operations and functions.

From launching programs and navigating in digital spaces to controlling various device functions, steering keys provide exceptional tools for ease of use in utilizing technology. This article explores the extensive applications of steering keys and examines how they function.

What is a Steering Key?

Keys, due to their vital role in electrical circuits, belong to a group called “steering keys.” These small components, in terms of power and size, are categorized into various types of manual and compound keys based on their internal mechanisms.

The function of these keys in electrical installations is to control processes and equipment. During a process, steering keys are used to start, stop, or modify circuit conditions. These keys can operate manually or automatically and, based on the number of states and plates, the open or closed position of contacts, lever or rotary movement of the handle, continuous or spring return steering, have different signaling and protective systems.

In this field, some of the equipment and keys used in steering circuits include contactors (magnetic keys), start-stop switches, thermal relays, magnetic relays, fuses, limit switches, pressure function keys, float keys, rotation function keys, sensors, and more. These diverse devices enhance efficiency and safety in electrical environments.

Pressure Function Keys (Gas Keys): Operation, Application, and Technical Principles

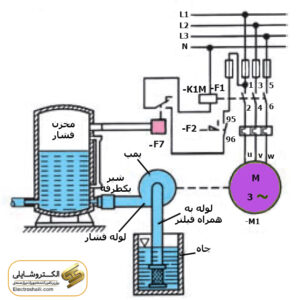

Pressure function keys or gas keys are among the diverse variations in the world of steering keys. These keys are used to control gas levels in tanks and compressors, regulate water pressure in pipes, and automatically activate these devices. The steering factor in these keys is the gas or liquid pressure inside the reservoir, and the key’s disconnect and connect factor is the gas pressure.

The working principle of these keys is that gas pressure creates a force equal to F=P.A (where P represents pressure, and A is the cross-sectional area of the plate). In relays, this force is transferred to the displacement of the plate and, through a lever, cuts or connects a contact.

The spring under the plate creates a returning force and, by selecting different springs, allows adjusting diff

erent pressures on the plate and disconnecting/connecting the contact as desired.

Float Keys: Applications and Structure

Float keys are essential tools in controlling the water or liquids level in water sources, pools, and reservoirs. The structure of these keys consists of a combination of a balance weight, a float part, and a microswitch. When adjusting the float part, with changes in the liquid level inside the reservoir, the float moves, and this positional change informs the microswitch within t

he key. This information is then sent to the control key, causing the circuit to be disconnected or connected.

With their unique structure, float keys not only provide

precise control of liquid levels but also offer capabilities for automatic decision-making and intelligent functions in various environments. These keys are easy to implement and install, demonstrating automatic responsiveness in effectively monitoring liquid levels.

In the diagram below, a circuit installation diagram for a float key for a water pump is presented, incorporating both a miniature key and a contactor. This smart circuit is designed to optimize water pump performance using the float key.

Using the miniature key, this circuit enables quick and

precise start-up and shutdown of the pump. Additionally, with the presence of the contactor in the circuit, an intelligent and automatic connection between the float key and the pump is facilitated. This smart connection helps improve energy efficiency and provides real-time monitoring of water levels in the water supply source.

With this innovative solution, the installation of a float key for a water pump becomes an efficient and intelligent process, contributing to the improved performance and durability of irrigation and water supply equipment.

In the diagram below, a circuit installation diagram of a float key is shown, utilizing a miniature key and a contactor along with the addition of a selector switch. This advanced circuit, by integrating the selector switch, provides broader capabilities for controlling the water pump’s operation.

The use of the miniature key in this circuit brings features such as quick and precise start-up and shutdown of the pump. Moreover, the presence of the contactor in the circuit helps optimize the pump’s performance. Adding a selector switch to this circuit allows choosing different operating modes for the pump, such as manual or automatic startup.

This intelligent circuit, utilizing the combination of the float key and the selector switch, aims to elevate the control and monitoring of the water pump to a higher level of efficiency and flexibility. This innovative solution contributes to enhancing the efficiency of irrigation systems and water supply, providing users with the flexibility to choose different control options.

Rotation Function Keys

Rotation function keys, also known as centrifugal or centripetal keys, are a crucial component in single-phase electric motors used for various applications, including removing the auxiliary winding from the circuit or creating counter-current brakes. The unique structure of these keys consists of a shaft and two weights that move by a collar and a spring. These two weights move proportionally with changes in the motor’s speed or the rotating device.

With an increase or decrease in speed, the weights on both sides move towards or away from the axis. This movement results in the displacement of the collar on the shaft, and consequently, the rotation function key is disconnected or connected. The mechanism of these keys contributes to improving the performance and efficiency of electric motors in different conditions, playing a significant role in controlling the current and speed of the motors.

Thermostats: Role, Types, and Applications

Thermostats, or temperature control keys, are sensitive tools to changes in ambient temperature used in various industrial devices. Their primary function is to maintain the thermal balance of the device and provide precise control in case of temperature increase or decrease beyond the set limit.

Thermostats are commonly used in heating and cooling devices such as heaters, refrigerators, and chillers. These keys are categorized into rod-type, gas-filled, and bimetallic types.

1. Rod-type: In this type, a rod is placed inside a tube with one end free. Changes in temperature cause the free end of the rod to move, which can either open or close a key.

2. Gas-filled: These keys use changes in gas pressure due to temperature variations to open or close the key. Increasing temperature raises gas pressure, opening the chamber, and decreasing temperature compresses the chamber, resulting in key disconnection.

3. Bimetallic: These keys use two dissimilar metal blades pressed against each other. Changes in temperature cause bending of these blades, leading to key disconnection or connection.

The diverse uses of these keys in heating and cooling devices, refrigerators, and heaters make them crucial components of modern industrial technologies.

Crane Control Key: High-Efficiency Control

The crane control key is a vital tool for managing and controlling overhead or gantry cranes. These keys, designed and manufactured by Schneider in two models – single-speed and two-speed, provide easy connection to the device using the provided cable, enabling better control and guidance of objects.

By choosing Schneider’s crane control key, the ability to perform operations with precision and high efficiency in crane control is achieved. With high build quality and extensive features, these keys stand out as essential tools in the field of crane equipment control and management.

Optical Electric Eye or Sensor: Remote Keystroke Technology

The optical electric eye or sensor is an advanced type of control key that reacts without the need for physical contact with hands or any other tools, covering distances from one millimeter to eight meters. This system is controlled by an internal smart relay, opening or closing contacts and providing instructions to the desired devices.

The use of this type of control key in industrial devices and production lines has become widespread due to its exceptional features and advanced capabilities. These sensors are produced in various types, including thermal, gas, magnetic, and capacitive.

Industrial Joystick: Precise Control with High Power

The industrial joystick is an advanced control handle that, by moving its lever and creating a mechanical state, generates specific electrical parameters. This tool provides precise and high-efficiency control, leading to the movement of objects in different directions.

With its high protection level, the industrial joystick is suitable for industrial automation systems. In mobile control stations and control panels, the joystick is used as a fundamental tool for controlling motor acceleration and managing motor on/off conditions. This tool ensures convenience and reliability in the performance of industrial systems.

Push Button or Push Switch: Tool for Precise Control of Circuits

The push button or push switch is a control tool and a type of command key used for manual opening and closing of contacts. In circuits using contactors, the push button is used as a means to provide instantaneous commands for starting or stopping work and even changing the circuit state.

By pressing the push button, all contacts change their state, and upon release, they return to their initial state. Emergency push buttons are typically red and serve as emergency cut-off devices, while stop-start push buttons act as on/off devices. Schneider Electric push buttons are produced in three types: metallic, plastic, and bakelite. The types of Schneider Electric push buttons include:

– Emergency: Used for emergency commands in electrical installations.

– Stop-Start: Buttons and control devices that, when manually triggered and in the command direction, cut off or connect the circuit.

– Double Stop-Start: Double buttons generally operate similarly to stop-start but with the difference that two control devices are in one button.

Selector Switch: Hand-Controlled Tool with Persistent State

The selector switch is one of the command keys controlled manually. These switches, including Schneider Electric equipment, have two positions, spring return to the center, and a persistent state. Most of these switches are made as two-position or three-position devices.

Selector switches that maintain their state stably in working or off conditions by turning the key are known as “keyed selector switches.” This manual control tool allows precise control and state changes in circuits in various systems.

Pull Cord Switch: Vital Tool for Safety in Production Lines

Among the vital tools in industrial control systems, pull cord switches, or conveyor belt cut-off switches, are introduced as an effective safety solution in production lines. These switches, operating with cable movements to the right, left, or from the sides, are used to cut off machine operations in case of potential accidents. The structure of these switches, similar to push buttons or push switches, utilizes force-sensitive moving systems, demonstrating innovation and efficiency in industrial control tools.

The conveyor belt emergency switch from Schneider Electric is categorized based on cable movements to the right, cable movements to the left, and cable movements from the sides. This vital tool is used as an effective safety solution in various industries such as steel production, welding machines, cutting machines, conveyor belts, printing machines, textiles, rolling mills, laboratory testing, paint production plants, tile and ceramic production plants, and more.

Limit Switch: Efficient Key for Motion Control

Limit switches are command keys used to control and restrict the movement of equipment and devices in mechanical processes. These keys come in various types, including simple, double, and multi-contact.

Limit switches play a crucial role in command circuits for controlling and restricting the movement of mechanical parts, changing the direction of movement, and also in timers and float switches, serving as essential keys for disconnecting or connecting. The structure of these keys, similar to push buttons or push switches, involves a force-sensitive moving system that either applies force to it or pulls it. In microswitches, similar to push buttons, the mechanical force applied to the lever releases the stored energy in the microswitch’s spring, returning it to its initial state.

Summary of Command Key Applications

Command keys play a vital role in today’s industry and are recognized as prominent control tools in industrial environments. Through unique designs and advanced technologies, these keys enhance the management and control of various equipment, including cranes, industrial machinery, and automation systems. Especially, Schneider’s crane control keys with two models, single-speed and two-speed, offering easy connection to devices and providing precise and effective control, are recognized as an excellent choice for industrial operations requiring high precision.

In this article, we have examined limit switches as command keys for controlling and restricting the movement of equipment and devices. These keys, with various structures and functions, including simple, double, and multi-contact, are used in command circuits to control and restrict the movement of mechanical parts and change the direction of movement, serving as essential keys for disconnecting or connecting.