Introduction to Industrial Power Distribution Networks

In industrial environments, the protection of electrical equipment and ensuring a reliable energy supply are of utmost importance. Industrial power distribution networks, as one of the essential infrastructural components of the industry, require the use of effective protective methods to maintain equipment stability and ensure continuous energy supply.

In this context, the selection of the most suitable protective relays is crucial. These relays are chosen carefully due to the significant role they play in ensuring the safety and proper functioning of electrical equipment. The importance of energy in industrial units and its role in the production process necessitate the precise selection of protective relays based on the type and characteristics of the required energy, following established standards.

In some cases, due to consumption constraints and the need for intelligent energy management, protective relays are used in conjunction with automatic circuits. These circuits, with precise and intelligent energy control, provide optimal energy supply while maintaining safety, achieving higher efficiency and productivity.

Ultimately, optimizing protective relays and automatic circuits in industrial power distribution networks enhances performance and ensures equipment stability. It also takes necessary measures against the risks arising from electrical currents and possible disruptions.

In addition to protective relays, automatic circuits are used for starting backup units and providing continuous energy to consumers in industrial units.

Features of High-Consumption Industrial Power Distribution Networks

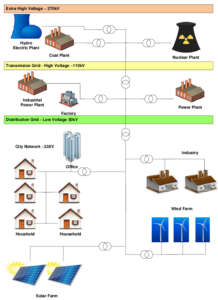

Designing industrial power distribution networks is a challenging process that depends on the varying needs and importance of energy for different industrial units. Industrial units are divided into two power consumption categories: units with consumption below 10-15 MW and high-consumption units exceeding 20 MW (around 100-200 MW). The energy consumption may be continuous with a constant or variable amount or intermittent, known as shock loads.

High-consumption industrial units include metal smelting units (steel, aluminum, copper) or chemical units (polymers, amines, petrochemicals) that typically have high production with power exceeding 20-200 MW. Energy supply for these units is carried out through distribution networks with voltages ranging from 400 to 630 volts because constructing separate power plants for them is not economical. These units may experience an immediate production halt in case of energy interruption.

To mitigate these risks, emergency energy generation units with separate and independent generators from the national grid are equipped. These units supply over 10-20% of their total consumption. The supply to these units is connected to the national grid through two main lines, reserve lines, and a strong pressure station within the industrial unit’s premises.

High-Consumption Industrial Power Distribution Network

The distribution system for high-consumption industrial units with over 20 MW power consumption is optimized by establishing a main station near the workshop or unit with the highest energy demand. Energy is transferred to the main station through transmission lines, and in this stage, 50-80% of it is consumed.

Subsequently, 20-30% of energy at the industrial unit level is distributed through distribution networks with voltages of 6-10 kV. The proximity between the main station and the distribution network enables the direct transfer of energy from the transmission row to the distribution row with lower voltages. For example, in metal production units such as aluminum and copper, the main station is established near the electrolysis lines. Energy is converted to direct current at the station and immediately feeds the electrolysis lines. The figure below details the aluminum production electrolysis line with a capacity of 100,000 tons per year and the 230 kV line for feeding the unit station.

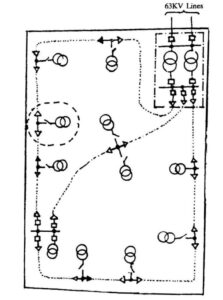

Generally, internal distribution networks in industrial centers require networks with various voltages. For instance, in metal smelting centers and iron and steel melting plants, distribution networks of 63 kV, 30 kV, 20 kV, 10 kV, 6.3 kV, and 4.3 kV are established, and energy is transferred from each row to the next row with lower voltage.

Energy transfer from high voltage rows to distribution voltage rows

The transfer of energy from high-voltage rows to distribution voltage rows, accompanied by a significant increase in the ability to connect short circuits and phase-to-phase fault currents, is discussed. The improper increase in short circuit capability in distribution networks goes beyond standard values, so appropriate methods are necessary to reduce this value to standard levels. As a result, estimating the short-circuit power in all industrial units with high consumption is emphasized and becomes a fundamental characteristic in these types of distribution networks.

Similar conditions are observed regarding increasing the short-circuit capability in the power plants’ internal consumption networks with high production capacity. Reducing this capability leads to cost reduction of network equipment, reducing the size of panels, and simplifying the circuits of protective relays and automatic control. Therefore, current-limiting equipment and reducing short-circuit power are the main predictions in the field of distribution networks.

Workshops and industrial units with uninterrupted power supply

In industrial distribution networks, the presence of workshops and production units with uninterrupted power supply is a prominent feature. These workshops and units provide energy continuously without any interruptions and are recognized as places with uninterrupted power.

To ensure continuous energy supply in these units and industrial centers, actions such as building emergency power plants, installing reserve equipment including transformer lines, predicting main busbars, and reserves, as well as installing NO or NC type disconnecting and connecting equipment are performed. Here, “NO” and “NC” refer to the status of the disconnecting and connecting devices. These devices operate in normal conditions (NO) but automatically change their status to NO or NC in emergency conditions caused by a fault or power outage in a part of the network or workshop.

In fact, estimating the short-circuit power in these types of units is of great importance. This estimation leads to cost reduction of network equipment, reduction in panel dimensions, and simplification of circuits for protective relays and automatic control. On the other hand, current-limiting equipment and reducing short-circuit power are fundamental predictions in the field of distribution networks.

Use cases of parallel operation of main feeders and transformers

The effective use of parallel operation of main feeders and transformers in transmission voltage systems is justified with the following cases:

Emergency situation: In case of line or transformer failures during operation, connecting and keeping the reserve lines and transformers powered ensures preventing the shutdown of synchronous motors and damage to the production process. This method reduces downtime and allows faster startup of motors.

Multiple connections: When different busbars are connected through different power sources, and connecting NO is not possible, this system avoids connecting two networks and does not introduce high time delay. These parallel connections improve the system’s performance.

Industrial load management: In cases where industrial loads have impulsive characteristics, a parallel system with different sources improves the ability to supply impulsive loads. This method is usually applied in cases where the load suddenly and momentarily increases and requires continuous disconnection of power.

Methods for mitigating impulsive loads in industrial consumers

To optimize the use of impulsive loads in industrial consumers, there are various engineering and executive solutions. Here are some of these solutions:

Development of impulsive energy: By installing additional energy production units near consumers with impulsive loads, the voltage improvement at the consumption site is achieved. This action reduces the strong pressure on the transmission network.

Independent impulsive load supply: Using separate feed lines from main production centers and substations with high capacity at the impulsive load site turns the primary substation under 63-400 kV transmission voltages into an effective solution.

Feed lines with minimum inductance: By predicting lower inductance specifications for feed lines, cable lines, or busbars with minimum inductance and with high capacitive properties without using series reactors can be utilized.

Two-winding transformers: Considering two-winding transformers, where one winding is for supplying impulsive loads and the other winding serves as a reserve, improves the system’s performance.

Independent feeders with low reactors: By preventing delays in impulsive loads and voltage fluctuations, various feeders are organized. The reactors used for constant loads reduce circuit inductance and control voltage fluctuations.

These solutions are designed to increase efficiency and system reliability against impulsive loads, playing a crucial role in optimizing the performance of industrial consumers with impulsive loads.

If, despite predictions for the uniform voltage characteristics of impulsive loads, it is affected by impulsive loads and experiences significant changes and fluctuations due to the lack of stability, additional equipment such as synchronous compensators specifically connected to the impulsive load power supply busbar and high-speed static compensating equipment are used.

Usually, industrial power networks are predicted radially with rows of different nominal voltages at the industrial unit level. This choice is made based on the importance of energy supply and the desired reliability in supplying energy to production units.

Units with exceptional reliability in energy supply through 2 or more lines as reserves, through different feeding paths, are powered. If the supply is from the central network and considering the possibility of power outage, two lines and two transformer units are used.

Voltage step values are selected based on the type of consumers and their required power. In simpler cases, two or three steps are used; for example, steps of 63 kV, 20 kV, 11 kV, and 6.3 kV. If the industrial unit is equipped with high-pressure motors of 3.2 kV or 6.3 kV, the motor feed line is supplied separately from a dedicated transformer.

If the number of high-pressure motors is limited, the motor feed network will be limited to a high-pressure panel and cable or busbar feed. Prediction allows the motor feed network to be considered separately and independently of the industrial distribution network, in the form of an isolated or earthed neutral network with high resistance.

Conclusion

In this article, we discussed industrial units with uninterrupted energy supply and compared them with industrial distribution networks. We also examined predictions and equipment required for continuous energy supply in these units.

Concepts such as the parallel operation of feed lines and transformers, the use of specific equipment for impulsive loads, and potential effects on industrial power distribution networks were thoroughly investigated. Finally, solutions and recommendations for improving energy supply and increasing reliability in industrial units were discussed.