Drive or Motor Inverter: What Is It?

A drive or motor inverter is utilized as an advanced technology for controlling electric motors and adjusting their rotational speed to enhance efficiency. These sophisticated electronic devices, leveraging transistor technology and modern electronic components, enable precise and dynamic control over the speed of electric motors. This technology not only aids in the precise management of motor speed but also provides additional benefits such as energy savings and increased efficiency.

The use of drives and inverters in industries, especially in cases where precise speed control and immediate changes in the performance of electric motors are required, is crucial. This technology plays a significant role in reducing energy wastage, extending the lifespan of equipment, and lowering maintenance costs. By harnessing the control capabilities of inverters, various industries, including electrical, metallurgy, oil and gas, and even automotive industries, enhance productivity and improve the quality of production processes.

In summary, the use of drives and inverters as advanced control devices in electrical and electronic equipment empowers industrial managers to intelligently and optimally elevate the performance of electric motors.

In this article, we delve into the details of drive operation, its prominent functions, advanced control methods, and finally, we examine reputable drive brands in the market.

History of AC Drive or Inverter Technology

In the past, for precise speed control of certain loads, DC motors were used. However, due to the high wear and tear of brushes and other components of DC motors, the use of induction motors and precise speed control gradually replaced them over time.

The first AC drive or inverter was introduced to the market in 1958 by an American company. Features and capabilities were progressively added to drives by other companies, leading to the introduction of inverters with better capabilities.

Currently, 10% of the total motors used worldwide are equipped with drives or inverters. This widely adopted technology has significantly strengthened its position in the industry by improving the efficiency and precise control of motors under various loads.

How Does Advanced Drive Technology for Electric Motors Work?

The electric motor drive, as a vital system in controlling the speed and rotation of electric motors, plays a crucial role. This device facilitates the continuous variation of the motor’s speed from zero to several times its nominal speed. By controlling the speed of electric motors, industrial operations become more flexible, and in many applications, energy efficiency is enhanced.

Moreover, with the use of drives, the starting current of the electric motor from the grid is significantly reduced. This means that the motor’s current consumption is considerably reduced compared to its nominal current.

Drives also provide the capability of soft starting and stopping the electric motor in a fully controlled manner. The start and stop times can be accurately adjusted, which may be within fractions of a second or even hundreds of minutes. The drive’s capability in soft starting and stopping contributes to a significant reduction in mechanical stresses in couplings and other rotating components.

How Is Motor Speed Precisely Controlled Using Drive or Inverter?

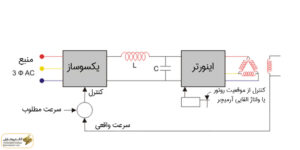

In the control system of induction motors, the drive acts as an intermediary between the power source and the motors. When AC voltage with a constant voltage and specified frequency enters the drive, this device is responsible for converting it into DC voltage with specific ripples. Then, using an intermediate circuit, the ripples are removed, and a stable DC voltage is obtained.

In the next stage, the drive converts this DC voltage into an AC voltage with variable voltage and frequency. By adjusting the output frequency and voltage in each drive, the user or operator can deliver the desired speed and torque to the motor according to the catalog and settings, thereby having precise control over the motor’s speed or torque.

Adjustable Parameters in the Speed Adjustment Process in Drives

In the process of speed adjustment in drives, various settings are possible that allow precise influence on the rotational speed of the electric motor shaft. By controlling the switches of the drive’s transistors, the amount of delivered frequency to the motor can be altered. Increasing the input frequency to the motor results in an increase in motor speed, while decreasing the frequency leads to a reduction in speed.

These changes in frequency and rotational speed parameters can be dynamically applied by the precise control of transistors in drives. In other words, by adjusting appropriate values, the performance of the electric motor can be optimized based on specific requirements, leading to greater efficiency in processes.

Methods for Advanced Control of Electric Motor Speed in Drives

In the dynamic and advanced world of industry, there are vital control tools to optimize the performance of various machines. Standard control methods in AC drives provide two approaches: scalar and vector (or field-oriented) control. Let’s delve into the details of these two approaches.

Scalar or V/F Control Method in Inverters:

This method, also known as Pulse Width Modulation (PWM), V/F frequency control, or VVVF, involves converting AC voltage to DC and then sending a pulsed sequence of variable-frequency voltage to the motor through a modulator.

In this method, the V/F ratio remains constant, and with an increase in frequency, the voltage also increases. There is no direct control over the motor’s torque, and changes in voltage and frequency indirectly control the motor.

Due to the lack of feedback, this method introduces a delay in responding to torque changes, reducing low-speed control efficiency.

Vector or Field-Oriented Control Method in Inverters:

This method is newer and more advanced compared to the scalar method. Addressing the drawbacks of V/F control, the vector control method provides effective control over the precise speed of electric motors.

In this approach, efforts are made to accurately control real motor control variables such as flux and torque. To control torque and flux, the motor current must be controllable. In these motors, current control is not applied as an independent system on the stator’s current. Instead, the motor’s current is considered as a function of the stator current, and complex mathematical calculations are used to control the flux.

In this method, fast-response transistors replace slow-response thyristors, improving speed control accuracy and reducing errors.

Comparison of V/F and Vector Control Methods

Smaller Dimensions in Vector Control Method:

In vector control drives, due to smaller transistor dimensions, the overall dimensions of the drives have improved compared to the V/F control method.

Control of Multiple Motors in V/F Method:

In V/F control, it is possible to control multiple motors simultaneously using a single drive. Vector control drives lack this capability and can only support one motor.

Two-Way Communication in Vector Method:

In vector control, a two-way communication is established between the electric motor and the inverter. The inverter decides how to change the frequency to reach the desired motor speed based on the feedback received from the motor. However, in the V/F method, the communication between the electric motor and the inverter is one-way.

Higher Precision and Minimum Error in Vector Method:

The vector control method, due to higher precision and minimal errors, provides better improvements in speed control. This possibility is not readily available in the V/F method.

Selection Criteria for Drive or Inverter Control Type

Selecting the most suitable drive or inverter control type should be based on factors such as starting torque at low speed, speed control range, and precision.

– V/F Method:

In conditions where the starting torque is low, and there are minor load changes, the V/F method is employed. This method performs well in applications such as pumps and fans.

– Vector Method:

In conditions where the starting torque is high, and there are significant load changes, the vector control method is useful. This method is primarily used in applications like cranes with prominent effects.

Advantages and Applications of Drives in Industry

– Optimal Speed and Torque Control:

Drives assist in optimal control of the speed and torque of electric motors.

– Energy Consumption Reduction:

The use of drives leads to a reduction in energy consumption in electrical systems.

– Soft Starting and Stopping:

Drives enable soft starting and stopping of electric motors, providing mechanical assistance to the system.

– Direction Change:

Drives facilitate a quick and easy change in the direction of electric motor rotation.

– Reduced Need for Auxiliary Protective Systems:

The use of drives reduces the need for auxiliary protective systems in electrical systems.

– Reduced Starting Current:

Drives result in a reduced starting current for electric motors, optimizing energy consumption.

Classification of Drives Based on Voltage and Power Parameters

Drives or inverters are classified based on their voltage class and power supply. These devices are commonly available in single and three-phase voltage classes with voltage ranges of 200, 400, and 690 volts in the market. These equipment range in power from 1.5 kilowatts and above.

It’s important to note that the voltage classes of each brand may vary, and details can be reviewed by referring to their catalogs.

Placement of Drives in Everyday Life

In recent years, the need for controlling the speed of electric motors in various industries has significantly increased. This surge in demand has led drives or inverters to find a more prominent place in our daily lives. For example, these devices are used in imaging devices in hospitals, elevators, escalators, conveyor belts in production lines, lifting systems, paper and leather industries, and many other applications.

Reputable Brands in the World of Drives:

– OMRON

– YASKAWA

– ABB

– LS Drive

– HYUNDAI

– DELTA Drive

Each of these brands provides powerful software that allows easy installation and settings for various types of motors with different specifications. Many of these drives also offer remote control capabilities through computers, allowing users to benefit from

user-friendly operation and intelligent control.

Conclusion

In this article, we explored the role and functionality of drives or inverters in controlling the speed and torque of electric motors. We first explained the structure and operation of these devices and then introduced well-known brands in this field, including OMRON, YASKAWA, ABB, LS, HYUNDAI, and DELTA.

Additionally, we discussed the methods of controlling electric motor speed in drives, their types, and the differences between V/F and vector control methods. Finally, we touched on the applications and advantages of using drives in the industry, such as energy consumption reduction and optimal control of motor speed and torque.