Phase Control: What is it? How does it work, and what components does it have?

Phase control, as one of the vital elements in three-phase systems, is of great importance. These devices act to protect the system against any voltage errors. The functioning of phase control involves simultaneously decreasing or increasing the voltage in three-phase systems. This essential task is crucial for protective purposes, as it prevents damage to electric motors and, consequently, protects machinery and personnel.

In phase control devices, various components such as relays, sensors, and transformers exist, each performing its specific functions. These equipment, in collaboration and precise coordination with electrical systems, provide the possibility of intervention and proper and timely control. Familiarity with the components and the role of each of these elements enables a deeper understanding of the overall functioning of phase control. Therefore, this article, with an educational and straightforward approach, delves into the details and performance of these components to equip you with the necessary knowledge in this field. Stay with us on this journey into the world of phase control.

What is Phase Control?

Phase control measures are crucial for the protection of individuals and electrical equipment. Faced with deficiencies in electrical energy management, the likelihood of damage and serious problems in loads and devices increases. With the increasing use of electricity in industries and homes, the need for complete protection of equipment and electrical appliances also grows.

One common challenge in thermal industries is a significant increase in temperature and damage to loads due to phase faults. Even with devices such as overload relays or circuit breakers for protection, electric loads require rapid responses to thermal and electronic equipment.

Phase control, designed as a type of control and monitoring relay, is intended to identify problems in three-phase power sources. Still, it can also be used for single-phase applications.

The phase control relay, in conditions such as complete phase loss, voltage below the acceptable level, excessive voltage, phase sequence, phase imbalance, and neutral losses, provides supervision. These relays can be installed on three-phase sources with or without neutral and are also referred to in the power market as phase protection relays, phase control relays, line monitoring relays, or phase monitoring relays.

What are the Benefits of Using Phase Control Relays in the Electrical Industry?

With the increasing number of motor coil turns, additional heat is generated that may lead to motor failure. This damage occurs irreversibly and ultimately results in coil short-circuiting and motor failure.

The reaction time of additional thermal load units may be time-consuming. The phase control relay plays a crucial role in effectively protecting against the extra heat generated by high currents. This action is performed by limiting the additional current, and the phase control relay helps in the following:

Increasing Motor Life:

With precise control of current and temperature, the life of the motor increases, requiring fewer repairs or replacements.

Reducing Repair Costs:

The use of phase control relays reduces the costs of repairing and replacing motors.

Reducing Downtime:

By limiting risks associated with motor issues, downtime is minimized.

Improving Safety:

The phase control relay enhances the safety of the electrical circuit by reducing the risks of electric shocks or fires resulting from coil short-circuiting.

Intelligent use of these devices can help improve efficiency and reduce maintenance costs while protecting equipment.

How does a Phase Control Relay Work?

Let’s explain the operation of a phase control relay in simple and understandable terms. These devices receive signals from input sources and process them. After a certain period, these signals reach a specific and constant value. At this point, the output announces its change in position. This output is connected to devices such as contactors and switches that can open or close the circuit or send an alert to the PLC system.

The phase control relay has one or more relay outputs that are typically set in fault tolerance settings. These relays, when the power supply conditions are within an acceptable range, activate or deactivate the circuit. In the event of one of the above faults, the outputs open, and the circuit is disconnected. This action is taken to protect the control system or machinery in the face of unfavorable power supply conditions, preventing any potential damage.

In summary, the phase control relay operates as a monitoring and control device designed to identify problems in three-phase power sources. Its outputs act as safety measures, disconnecting the circuit when necessary to safeguard control systems or machinery from undesirable conditions.

Phase control is the act of controlling voltage levels in three-phase systems simultaneously, playing a crucial role in protecting the system against voltage errors. It involves adjusting the voltage in three-phase systems to prevent damage to electric motors and ensure the safety of machinery and personnel.

In phase control devices, various components such as relays, sensors, and transformers work together to monitor and control the system. These components, in coordination with electrical systems, allow for intervention and precise control. Understanding the role of each component is essential for a deeper comprehension of phase control.

Phase Control Relay: A phase control relay, also known as a control and monitoring relay, is designed to detect issues in three-phase power sources. It provides supervision in conditions such as complete phase loss, low or excessive voltage, phase sequence, phase imbalance, and neutral losses. These relays are crucial for protecting electrical circuits and machinery.

Benefits of Phase Control Relays: Phase control relays contribute to increasing motor life, reducing repair costs, minimizing downtime, and improving safety. By precisely controlling current and temperature, these relays enhance the overall efficiency of electrical circuits, reduce maintenance expenses, and protect equipment.

How Phase Control Relays Work: Phase control relays receive signals from input sources, process them, and, after a certain period, change their output position. The relay outputs act as safety measures, disconnecting the circuit when necessary to safeguard control systems or machinery from undesirable conditions.

Components of Phase Control: The main components of phase control include multiple terminals (R, S, T or L1, L2, L3) for connecting three-phase input power, a sensitivity adjustment for detecting phase imbalances, an On Delay adjustment for setting waiting times, and control terminals (15, 16, 18) for receiving commands and transferring outputs. The relay also includes indicators for fault conditions.

Understanding these components is crucial for mastering the functionality and safety of phase control systems.

Control phase has several components:

Complete knowledge of the components of the phase control is a fundamental aspect in electrical science. Each phase control relay has multiple terminals and LED indicators, which may vary slightly depending on the manufacturer’s design. However, generally, these devices have several main sections, each of which we will examine below:

Multiple terminals (R, S, T) or (L1, L2, L3):

These terminals are used to connect the three-phase power input from the grid to the phase control relay. These terminals are independent of neutral connection and, when properly connected, indicate a power-on status.

Sensitivity (sen):

This screw is used to adjust the sensitivity in detecting phase imbalances and can optimize the sensitivity level.

On Delay:

This screw is used to set the waiting time during faults or the first activation of the circuit.

Terminal number 15 of the phase control (command input):

This terminal receives the command input and can transfer its output to terminals 18 and 16. This input acts as the COM base for the internal relay.

Terminal number 16 (normally closed or output):

This terminal is connected in the absence of faults in the three-phase voltage and indicates an active status. A contactor is connected to this terminal.

Terminal number 18, output, or normally open:

This terminal is closed in inactive states or in case of internal relay failure. Its function is monitoring and connection to the PLC.

Fault indicator:

In normal conditions, two to three fault indicators are displayed on each control. In special conditions such as swapping two phases out of three or voltage out of the allowed range, the fault indicator lights up.

Mastering these sections helps improve the performance and safety of phase control systems.

What is the application of the phase control relay?

The use of phase control relays in various applications brings numerous advantages. With high flexibility and efficiency, these devices are used in diverse fields:

Control of mobile equipment connections:

Among the main applications of the phase control relay are the control of connections for mobile equipment such as air conditioning compressors, trucks with refrigerated containers, and cranes.

Protection against reverse motor operation:

In applications where motors operate in reverse, such as elevators, displacement systems, escalators, etc., the phase control relay acts as an excellent protective system.

Preservation of sensitive three-phase resources:

These devices act as guardians of the sensitivity of three-phase systems, ensuring their proper functioning.

Preventing motor overheating due to asymmetric voltage:

The phase control relay continuously monitors phase voltages and prevents motors from overheating in case of imbalance.

Protection of power plants against destruction due to overvoltage:

In power plants, phase control relays are used to prevent destruction resulting from a sudden increase in voltage.

For drive rotation:

In various types of drives and rotation systems, the phase control relay is used as a crucial element for the proper control of voltage and phases.

Smart use of the phase control relay improves the efficiency of systems and prevents risks resulting from voltage and phase mismatches.

Guide to choosing the phase control relay

In choosing the phase control relay, considering the correct parameters is of utmost importance. First, ensure what resources you have and how many output relays your system needs. Polar-changing single or double-pole outputs are commonly seen, but if more are needed, protective relays are also available.

In the next step, evaluate what monitoring functions your system needs. Although phase loss is considered standard, additional functions such as low voltage, phase sequence, and phase fault may also be considered.

Consider the following parameters when selecting the phase control relay:

Voltage control:

Evaluate whether the relay can control various voltages and align with the system’s needs.

Function:

Select the type of relay function, such as low voltage, phase sequence, and phase fault, based on your system’s specific needs.

Number and type of output contacts:

Determine the size and type of relay outputs based on the specific connections of your system.

Range for setting maximum and minimum voltage threshold values:

Ensure that the relay can adjust the voltage range and be compatible with environmental conditions.

Setting the response delay range:

Specify the time range in which the relay should respond to faults and failures for optimal system performance.

By observing these parameters, the selection and use of the phase control relay contribute to improving the performance and safety of electrical systems.

When does phase failure occur?

Facing conditions of phase failure can quickly lead to serious damage in electrical systems. Below, we detail the types of these failures and their effects:

Phase loss:

When one or more phases are lost, motors may fail to start or lose their proper function. This leads to an increase in current up to 600% and excessive motor heating.

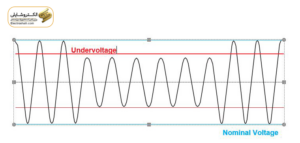

Under voltage:

Voltage lower than the minimum specified for the motor creates more current, which may damage the motor.

Overvoltage:

Excessive voltage damages the motor and can lead to its failure.

Phase sequence:

If phases are not connected in the correct order, starting the motor with an incorrect phase sequence can damage it.

Phase imbalance:

Phase imbalance occurs when the load in three phases is not properly balanced and can cause thermal stress and damage to motors and pumps.

Neutral loss:

Losing neutral increases voltage in single-phase low-current devices connected between a phase and neutral. This can make the voltage in the system hazardous.

Summary

Phase imbalance is a common issue in electrical systems that can result from various factors such as blown fuses, increased thermal load, broken wires, worn contacts, or mechanical failures. Timely detection of this phase imbalance is of utmost importance as it can quickly lead to unsafe conditions and serious damage to equipment.

A practical and economical solution to address this issue is the use of a phase control relay. The installation and setup of this device are straightforward, and it is considered an economic investment in ensuring the safety of electrical equipment. Various models of phase control relays are available in the market, and providers offer various types of protection. These devices work with a wide range of voltage and are adaptable to most three-phase applications.