Types of Transformers and Their Equivalent Circuits

In this article, we aim to explore the various types of transformers and their equivalent circuits. Transformers are recognized as fundamental tools in the field of electricity, transferring electrical energy from one circuit to another. These electromagnetic devices transform electric current based on the principles of changing magnetic fields on a core.

In this discussion, we will delve into various types of transformers, including power transformers, current transformers, and communication transformers, and also examine their equivalent circuits.

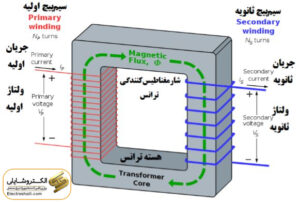

What is a Transformer?

A transformer is an electrical device that transfers electrical energy from one level to another. This device is used for voltage, current, and power reduction or increase in power networks and industries.

The operation of a transformer is based on the magnetic induction between wire coils, which transfers energy from the primary coil to the secondary coil. In this process, the type and amount of energy do not change, but voltage and current vary. The working principles of transformers are based on mutual induction in the wire coils.

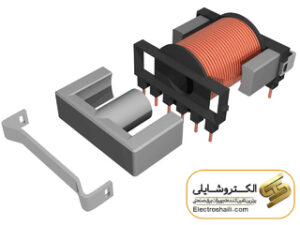

Transformer Structure

The structure of a transformer consists of two wire coils and a magnetic core: the primary coil and the secondary coil. The primary coil, through the wire coil, transfers the magnetic field to the core, creating a magnetic current in the secondary coil. The secondary coil is another type of wire coil that converts changes in magnetic current into electrical current.

The transformer core, acting as the heart of the transformer, is responsible for transmitting the magnetic field and energy conversion. The transformer core structure is designed as laminations with approximately 0.3 millimeters thickness per layer. Overall, the transformer core facilitates the transfer of voltage from the primary coil to the secondary coil. Without the core, due to magnetic scattering, the induction of voltage would not be possible.

Transformers can be categorized as either step-up or step-down. If the number of turns in the wire coils is multiple, the transformer is technically known as a step-up transformer, whereas if the output voltage is lower than the input voltage, it is recognized as a step-down transformer.

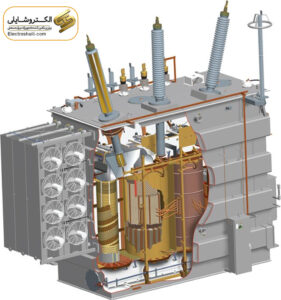

Transformer Components

A transformer, as a complex device in electrical systems, is comprised of multiple components, each with its specific functions. These components include:

Core:

– As the transformer’s heart, the core is responsible for transferring the magnetic field and energy conversion.

Wire Coils:

– The primary and secondary wire coils, respectively, transfer the magnetic current from the source to the core and from the core to the load.

Oil Tank:

– Serving for cooling and insulation, the oil tank is a crucial element in the transformer.

Radiator:

– Used for enhancing heat transfer and cooling the oil tank.

High and Low-Pressure Bushings:

– Utilized for connecting wire coils to transmission lines and performing electrical operations.

Tap Changer and Its Mechanism Panel:

– Used to regulate voltage and current and make changes within a specified range.

Control Panel:

– Used for controlling and managing transformer operations and communicating with the power system.

Measurement and Protection Devices:

– Including sensors and necessary devices for measuring and monitoring transformer parameters.

Valves and Communication Pipes:

– Used for connecting and communicating between various transformer components.

Cooling Devices:

– Components such as pumps and cooling systems to maintain the desired temperature inside the transformer.

Current Transformer:

– Used for transferring current without changing voltage.

Chassis and Wheels:

– Structural components for installing, transporting, and moving the transformer.

Transformer Operation:

The operation of a transformer is based on two fundamental principles:

Electromagnetic:

– Alternating current has the ability to create a variable magnetic field in the transformer’s core. This magnetic field, enclosed within a coil, induces an alternating current in the secondary coil.

Transformer as an Energy-Transfer Device:

– This device transfers electrical energy from one circuit to another. In general, two wire coils, primary and secondary, are connected with different voltages through a core. If the voltage in the primary coil increases, this change is transferred to the secondary coil, creating a current in it.

Specifically, a transformer, using components such as the core, wire coils, oil tank, radiator, high and low-pressure bushings, tap changer, mechanism panel, control panel, measurement and protection devices, communication pipes, cooling devices, current transformer, and chassis and wheels, is constructed. These components, through cooperation and coordination, enable the operation of the transformer and make the transfer of electrical energy possible.

Ideal Transformer:

An ideal transformer is a crucial device in the distribution and transmission of electrical energy, efficiently transferring energy from one level to another. In this transformer, magnetic flux from the primary coil is transferred to the secondary coil, creating an electric current in both coils.

The main feature of the ideal transformer is the use of a core with variable magnetic flux factors. These factors enhance energy transfer efficiency and reduce losses due to magnetic scattering.

Using this technology, ideal transformers are employed as a stable energy source for various systems. Economically and functionally, these transformers are highly efficient, playing a significant role in energy transfer with minimal losses.

However, to prevent power loss in an ideal transformer, attention to voltage regulation and phase difference is essential. Additionally, the use of advanced technologies in designing and manufacturing these devices helps improve performance and reduce losses.

In various applications, ideal transformers use identity-based methods, such as using variable magnetic flux factors, to transfer energy with minimal losses. These transformers are used as essential components in welding equipment, mercury vapor lamps, and neon signs to ensure safety in applications prone to short circuits.

Transformer Equivalent Circuit:

In the electrical world, the transformer equivalent circuit is a vital component for understanding the transformer’s operation and performing accurate calculations. This circuit represents the effect of mixed magnetic flux in the transformer core with simpler electrical circuits.

In this circuit, the transformer equivalent circuit acts as a representative of the transformer’s behavior. This circuit provides information about voltage and current in transformer wires using equation relationships.

The features of this circuit include resistances RS and RP, representing series and parallel resistances in transformer wire coils, respectively. These resistances play a primary role in changing voltage and current.

By analyzing the properties of leakage flux, the equivalent circuit displays self-inductances XP and XS separately. These self-inductances are placed in series with the wire coils and affect the electrical characteristics of the transformer.

In this circuit, iron losses are divided into two categories: eddy current losses (Foucault) and hysteresis losses, both influencing the performance and efficiency improvement of the transformer. A detailed analysis of these circuits is a fundamental tool for electrical engineers and specialists to enhance transformer performance and reduce losses.

Losses in Transformers and Equivalent Circuit:

At constant frequency, losses in transformers are directly related to the square of the core flux. These losses, directly proportional to the input voltage, can be modeled as a parallel resistance in the transformer circuit, known as RC.

A core with limited permeability requires current to maintain magnetic flux. Changes in magnetic flux in core currents will have in-phase changes with changes in magnetic flux. With the presence of core saturation permeability, two separate branches play a role, and resistances RS and RP accompany changes in magnetic flux.

In sinusoidal sources, magnetic flux 90 degrees from the induced voltage will be lagging. This can be considered as a parallel branch with iron losses RC and XM in parallel with the iron losses and XM, and this magnetic branch is called the magnetizing branch.

When the secondary coil of the transformer is open, the no-load current passing through the magnetizing branch is known as the current I.

Resistances RS and XS on the secondary side must be transferred to the primary side. These resistances represent copper losses and leakage in the secondary side and are placed in series with the secondary coil. This equivalent circuit is used in the detailed analysis of transformers in certain applications.

Types of Transformers Based on Core Type

First Type: Air Transformers with a core made of non-metallic materials such as plastic or wood.

Second Type: Oil Transformers with a core made of iron or steel and filled internally with a specific oil.

Autotransformer:

An autotransformer is a special type of transformer where the primary and secondary windings are partially intertwined. In other words, part of the primary winding is also used as the secondary winding. Due to its unique structure, this type of transformer usually allows for smaller size and lower weight compared to regular transformers.

Scott Connection or T Connection:

Scott Connection or T is a type of transformer connection used for specific applications, such as connecting motors to the power grid. In this type of connection, three primary windings of the transformer are connected in the form of a T. This connection helps regulate voltage and current for motors and is recognized as an efficient method for energy transfer to motors in various industries.

Types of Transformers Based on Application

Power Transformer:

Power transformers are used to convert voltage levels in power plants and high-voltage substations. This type of transformer is used for applications such as the aluminum smelting process in furnaces.

Distribution Transformer:

Distribution transformers are used to create a neutral point for detecting ground faults and phase imbalances in loads for distribution of energy in urban and industrial areas through ground and overhead substations.

Current Transformer (CT):

Current transformers are used for measuring current and protecting circuits against overcurrent or short circuits.

Voltage Transformer (PT):

Voltage measurement and protection against voltage are performed using voltage transformers.

Capacitive Voltage Transformer (CVT):

CVT is used for voltage measurement and protection, operating based on capacitive voltage division. This type of transformer is used for exchanging telecommunication signals on high-voltage lines.

Matching Transformer:

Matching transformer or Maching transformer is used for differential protection with a converter and balancing the primary and secondary currents of the transformer. This type of transformer is used precisely in protective circuits to balance the primary and secondary currents of the transformer, increasing efficiency and accuracy in detecting faults and protecting equipment.

Types of Transformers Based on Insulation and Cooling Medium:

Oil Transformers:

Oil transformers use oil as an insulation and cooling medium. These transformers are usually used in power plants and large networks, benefiting from the high thermal and insulating properties of oil for energy transfer and distribution.

Dry Transformers:

Dry transformers use solid insulating materials to prevent the need for oil as an insulating medium. This type of transformer is suitable for environments where oil maintenance is not possible.

SF6 Gas-Insulated Transformers:

SF6 gas-insulated transformers use SF6 gas as an insulating medium. This gas is an excellent cooling and insulating agent and is typically used in equipment with high voltage and a need for compact insulation.

Types of Transformers Based on Winding:

Single-Phase Transformer:

In a single-phase transformer, one phase wire and one ground wire are used to transfer energy. The windings are wound separately for each phase. This type of transformer is typically used in low-power and small-size applications.

Two-Phase Transformer:

In a two-phase transformer, two-phase wires and one ground wire are used to transfer energy. This type of transformer is commonly used in medium to large applications, such as in industry and energy distribution.

Three-Phase Transformer:

The winding of three-phase transformers is designed in a way that the primary and secondary windings are intricately connected in three phases. This type of transformer is typically used in power grids and power plants for the transmission and distribution of large loads. Three-phase transformers are widely used due to their high efficiency and effectiveness in energy transfer on a large scale.

Types of Transformer Windings Connections:

Star-Star Connection (Yy):

In this type of connection, the primary and secondary winding wires are connected in a star configuration. This connection is suitable for bidirectional power transfer and applications that require voltage increase.

Star-Delta Connection (Yd):

In the star-delta connection, the primary winding is connected in a star configuration, and the secondary winding is connected in a delta configuration. This connection is used for voltage increase and current reduction in distribution systems.

Delta-Delta Connection (Dd):

In the delta-delta connection, both primary and secondary winding wires are connected in a delta configuration. This type of connection is suitable for high-power transfer and high currents.

Delta-Star Connection (Dy):

Delta-star connection means that the primary winding is connected in a delta configuration, and the secondary winding is connected in a star configuration. This connection is used for voltage reduction and current increase in distribution systems.

Star-Star Connection with Neutral (Yy(dt)):

This type of star-star connection with a neutral point is suitable for maintaining voltage balance in systems with variable loads.

Parallel Operation of Transformers: Power Optimization and Performance Enhancement

In energy distribution stations, to increase power and achieve higher efficiency, multiple transformers are often combined in parallel. This parallel connection must be carefully established, adhering to specific conditions to ensure optimal performance and system stability.

Important Conditions for Parallel Operation of Transformers:

Equal Rated Voltage:

The rated voltage of both primary and secondary winding wires of transformers must be the same to ensure uniform distribution of currents.

Same Grouping:

Transformers must be of the same type and model to have matching voltage and current performance.

Equal Impedance:

The impedance of the short-circuit connection of transformers must match to achieve balance in currents.

Phase Connections:

Phases with the same names of transformers should be connected to each other for current coordination.

Equal Turns Ratio:

The turns ratio of the winding wires of transformers must be the same for uniform output voltage.

Equal Voltage Impedance Percentage:

The voltage impedance percentage of both transformers must be the same to maintain balance at different points.

Equal Resistance to Reactance Ratio:

The resistance to reactance ratio of both transformers must be the same to maintain stability in the system.

Proper use of transformers in parallel is one of the solutions for increasing efficiency and optimizing energy distribution.

Eddy Currents

Eddy currents refer to the phenomenon of electric currents circulating in molten cores containing ferromagnetic impurities. In this context, the cores have low or no magnetic properties. The currents in these cores move in magnetic eddies around various points in the core.

In other words, in materials with variable magnetic properties under the influence of a magnetic field, electric currents circulate inside them in eddy currents, forming magnetic eddies around different points in the core. This phenomenon can have various side effects on materials, including electrical losses, voltage drops, and heat in the core. In eddy currents, electric currents move in the core from one diameter to another, and this phenomenon may be caused by changes in the magnetic field over time or temperature.

Eddy currents are primarily important in electrical equipment and motors that use ferromagnetic materials. This phenomenon can lead to energy losses, voltage drops, and the need for precise design and effective protection in electrical systems.

Final Words

In this article, various types of transformers were explored in terms of structure, application, and technical features. From power transformers in power plants and high-voltage substations to current and voltage transformers for measurement and protection, a brief overview of different types was provided.

Additionally, important points such as winding connections, how to parallel transformers, and the importance of matching conditions in these connections were discussed. This article has provided the reader with extensive information on transformers and contributed to a better understanding of these crucial devices in electrical systems.